Leopold Deigner sen. (1896 – 1975)

Kammfabrik Deigner

1908: With twelve years, after completion of primary school, the German-Hungarian serves a three-year apprenticeship in Óbuda (Alt-Ofen). From his master Mr Komáromi he learns the traditional horn comb-making. In the same company he takes both his journeyman and his master’s examination successfully. Until military service, he continues to work in the workshop of his master.

1918/1919: Leopold Deigner returns home after the end of World War I. He starts his own comb factory in Törökbálint (Großturwall), a suburb of Budapest.

1920: In Budaörs (Wudersch), also a suburb of Budapest, Leopold Deigner buys a building site in order to first build a workshop and one year later a house.

1946: After World War II the Deigner Family is affected by the expulsion of Germans from Hungary. They are relocated to Cleebronn in southwestern Germany. Quickly they manage to build up their own comb factory.

Elisabeth Totzl, Katharina Dußle

and Theresia Wöhr

1975: Even after the death of Leopold Deigner the Kammfabrik Deigner (comb factory) remains a family business. The three daughters, Elisabeth Totzl, who completed – as the first woman ever – a three-year horn comb-making apprenticeship back in Hungary, Katharina Dußle and Theresia Wöhr continue the company.

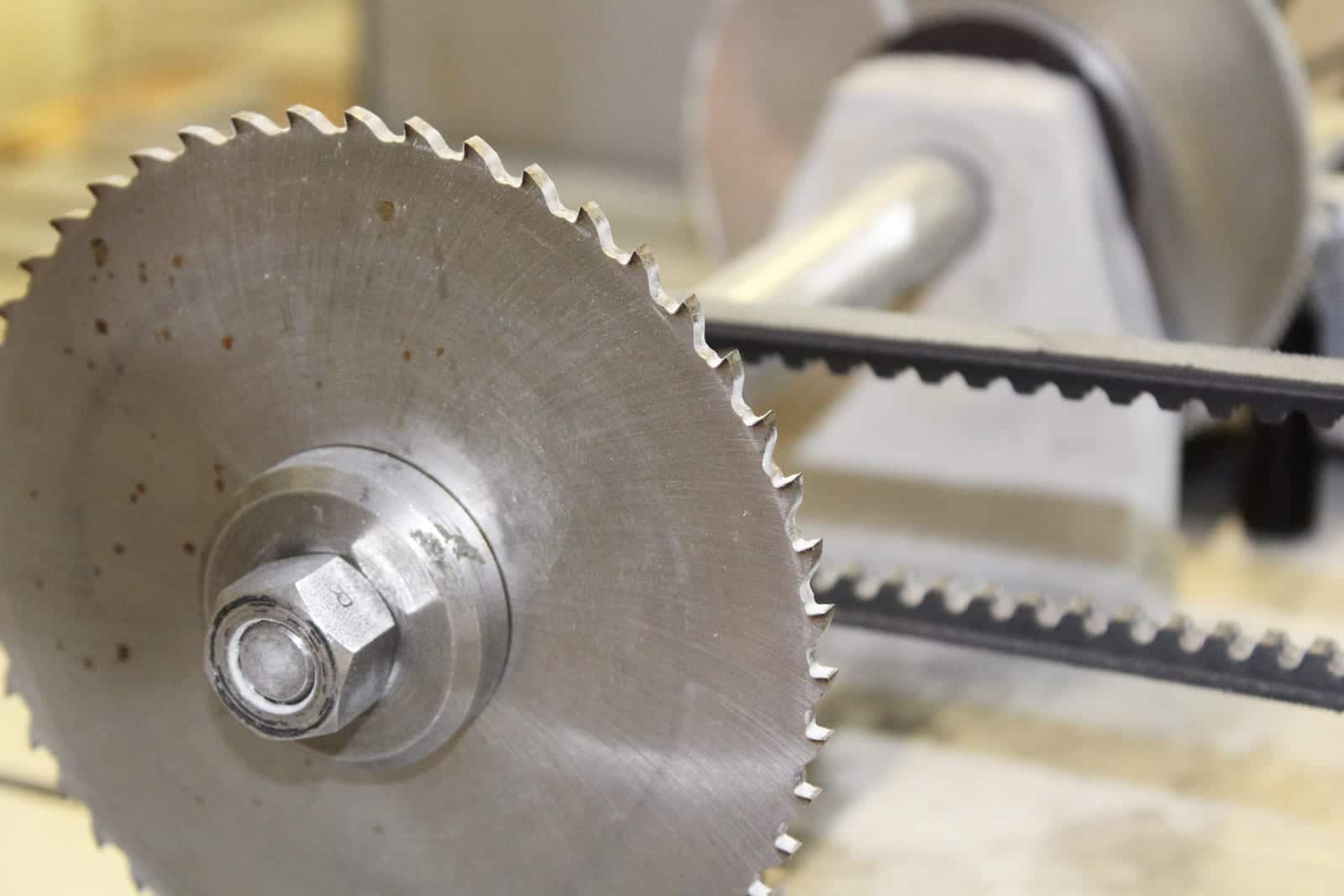

1987: The television station WDR visited the comb factory in Cleebronn to film the factual story, “Hornkamm” (horn comb) for the show “Die Sendung mit der Maus“. In the broadcast of 1988 Elisabeth Totzl, Katharina Dußle, Theresia Wöhr and her son Lothar Wöhr show, according to the individual production steps, how a horn comb is formed.

Theresia Wöhr and Lothar Wöhr

Hornverarbeitung Wöhr

1993: Theresia Wöhr and Lothar Wöhr continue the family tradition in Cleebronn. From 2000, Lothar Wöhr is the sole manager of the company Hornverarbeitung Wöhr.

Lothar Wöhr, Teresa Thomas and Jason Thomas

Hornverarbeitung Thohr

2008: Teresa Thomas (daughter of Lothar Wöhr) and Jason Thomas acquire the new headquarters of the company Hornverarbeitung in Widdern. After more than 9 decades of corporate history, the continued existence of the company is assured by Teresa and Jason Thomas, who are learning the traditional craft from Lothar Wöhr. In addition to horn combs a broad range of exclusive utensils, accessories, care items and jewelry made of horn and other natural materials are offered. Also customized products are part of the repertoire.

2014: From now on the products are distributed under the new name “THOHR” (THOmas & wöHR).